A fourth generation sock maker, John was hired by Smartwool in 2001 to help the company diversify its manufacturing base in order to meet the demand for its increasingly popular wool socks. Wool socks were not commonly knit by American mills and posed a challenge for those unfamiliar with the fiber. Ramsey’s expertise made him the perfect scout to find a good fit for Smartwool.

“Because I come out of the industry, I knew Harriss & Covington by reputation,” Ramsey said. “In conducting my research, talking to other manufacturers, everyone I asked had great things to say about the company and the family who ran it. So I knew of them and wanted to give them a call.”

“I instantly knew we shared the same views and values about business and partnership.”

– John Ramsey, Smartwool Director of Development

Coincidentally, around that same time, Tyler Covington made a prospecting trip to Outdoor Retailer, a major trade show in Salt Lake City. He stopped by the Smartwool booth and someone gave him Ramsey’s card. “I can’t remember who called who first,” Ramsey said, “but we met in a parking lot in Chattanooga in November of 2001. By early spring of 2002 we were working together. It was a rapid romance.

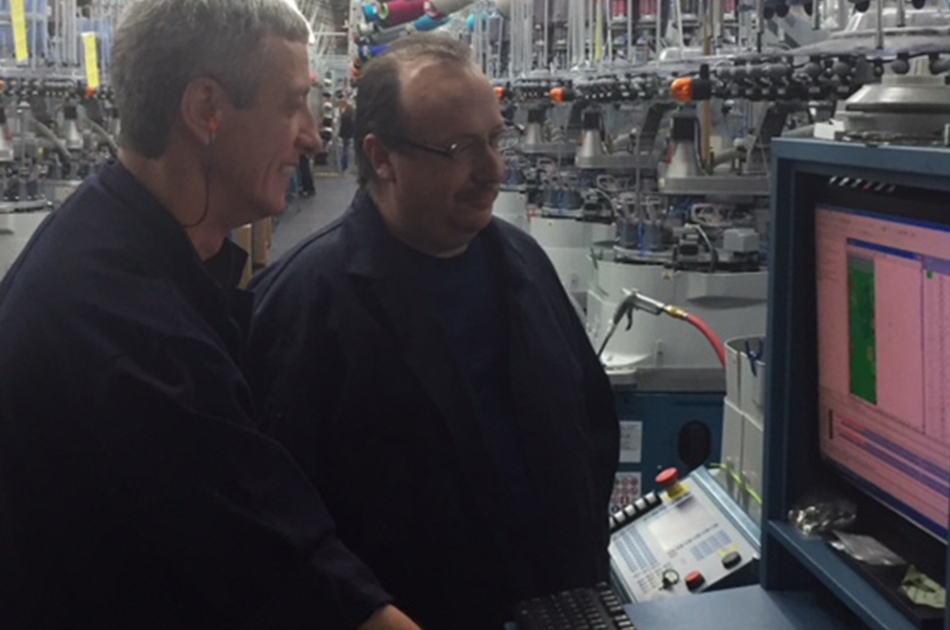

“I instantly knew we shared the same views and values about business and partnership. We were looking for a partnership. Additionally, when I toured the facility and met the people, I got the sense of a company that wanted to innovate, they wanted to explore, they were interested in a challenge. They were willing to invest, and I knew it would take an investment in newer knitting machine technology.”

The relationship began in earnest. Ramsey shared his knowledge of wool and knitting with the Harriss & Covington team. And the company responded by making the necessary investments in technology. “I can remember the first 10 machines they brought in specifically for us,” Ramsey said. “They were the most technically advanced of the time, and we started sampling. Ten styles turned to 30, 30 became 50 and now we have 180 specifically for Smartwool.”

Fifteen years into the partnership, Ramsey couldn’t have scripted it any better. “Internal talent is the main thing we look at,” he said. “You know, anyone can buy machines. But very few know how to run them.

“Here we are after all this time and Harriss & Covington still finds ways to surprise us. They are always pushing the envelope, and of course at Smartwool we do, too. We ask, ‘Can you do this?’ And they never say no. They say we’ll take this to Jackie or Eddie or Ricky, and see what we can do. They’re a one-stop shop with incredible people.

“The spirit of innovative thinking is on both sides” Ramsey added. “We go to them, they come to us. We couldn’t have asked for a better partner for us and our business. They have allowed us to innovate and that is how we stay ahead of very competitive marketplace.”

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

We have a diverse bank of single cylinder and double cylinder jacquard knitting equipment. Our core focus is single cylinder, and our machines span 108n to 200n with the vast majority being 144n. Our double cylinder machines are 144n. Over the past several years, Harriss & Covington has made significant investments in state-of-the-art knitting machines with toe closure. Nearly all our equipment is selective terry capable, allowing us to add targeted cushioning in select zones for specific applications and activities.

“We were looking for a partnership. Additionally, when I toured the facility and met the people, I got the sense of a company that wanted to innovate, they wanted to explore, they were interested in a challenge.”

John Ramsey, Smartwool®

Fully automated, microprocessor-controlled dye equipment ensures consistency and range from smaller sample machines up to 400-pound production machinery. Dryers are also fully automated.

“The timing was good and we felt a connection right from the start, Harriss & Covington being a family business like ours. Secondly, we think alike in terms of the partnership model. We both take the long-term view. Not just an order here or there.”

Joe & John Gaither, Feetures

Combining electric heat and steam applications ensures the very best layout dimensions as specified by our customers. Every sock — children to men’s extra large sizes — is inspected post-boarding for proper size, fit, about dimensions, shade consistency and any detectable defect.

“The spirit of innovative thinking is on both sides. We go to them, they come to us. We couldn’t have asked for a better partner for us and our business. They have allowed us to innovate and that is how we stay ahead of a very competitive marketplace.”

John Ramsey, Smartwool®

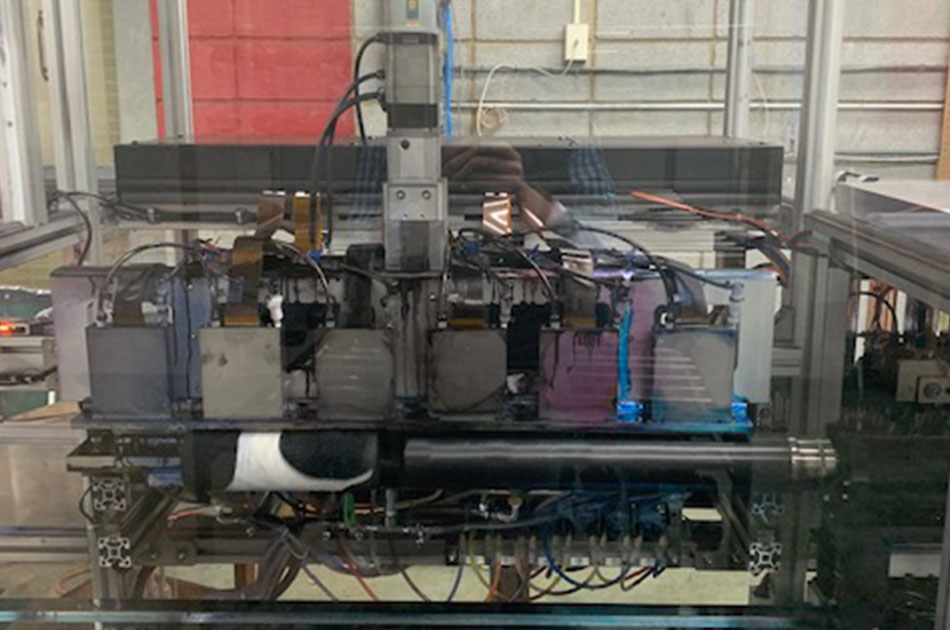

Unlike traditional textile printing methods such as heat transfer or dye sublimation, DTG printing uses specialized ink in order to print directly onto the garment giving the company the ability to print more specialized artwork, smaller runs and more customizations for customers.

“From the first meeting with Harriss & Covington, I knew there was something special about these guys. It was a like-minded business, similar in size and goals, and I always look for that. If you’re not matched up there, it won’t work. A huge company has different goals than ours, and one that is too small may not have the expertise or be able to stretch or change direction or go really fast when you need to.”

Justin Cleveland, Allbirds

High-volume multiple packs, specialized hanger packs, cardboard inserts, swiftachs, automated bagging lines, sole transfer — our packaging and folding department is equipped and experienced in every demand.

“Here we are after all this time, and Harriss & Covington still finds ways to surprise us. They are always pushing the envelope, and of course at Smartwool we do, too. We ask, ‘Can you do this?’ And they never say no.”

John Ramsey, Smartwool®

Error-free shipping and distribution to thousands of customer-specific destinations from our state-of-the-art warehouse. The latest computerized barcoding and check-weighing technologies track and monitor made-to-order, on-demand, case stock, pick-pack orders from shelf stock and case shipments that include all types of in-store displays.

“The timing was good and we felt a connection right from the start, Harriss & Covington being a family business like ours. Secondly, we think alike in terms of the partnership model. We both take the long-term view. Not just an order here or there.”

Joe & John Gaither, Feetures

More than 150 years of collective experience fuels an R&D department outfitted with the latest CAD systems. Whether it’s developing new and exciting products or executing quick tuns on samples, Harriss & Covington’s R&D delivers for our customers.

“The spirit of innovative thinking is on both sides. We go to them, they come to us. We couldn’t have asked for a better partner for us and our business. They have allowed us to innovate and that is how we stay ahead of a very competitive marketplace.”

John Ramsey, Smartwool®

Comprehensive, military-standard methodology audits quality at every stage of manufacturing, applying a pass/fail at every point through the process. For nearly a century, Harriss & Covington’s reputation for quality has been unsurpassed.

“From the first meeting with Harriss & Covington, I knew there was something special about these guys. It was a like-minded business, similar in size and goals, and I always look for that. If you’re not matched up there, it won’t work. A huge company has different goals than ours, and one that is too small may not have the expertise or be able to stretch or change direction or go really fast when you need to.”

Justin Cleveland, Allbirds

Copyright 2005 - 2025 Harriss & Covington Hosiery Mills, Inc.